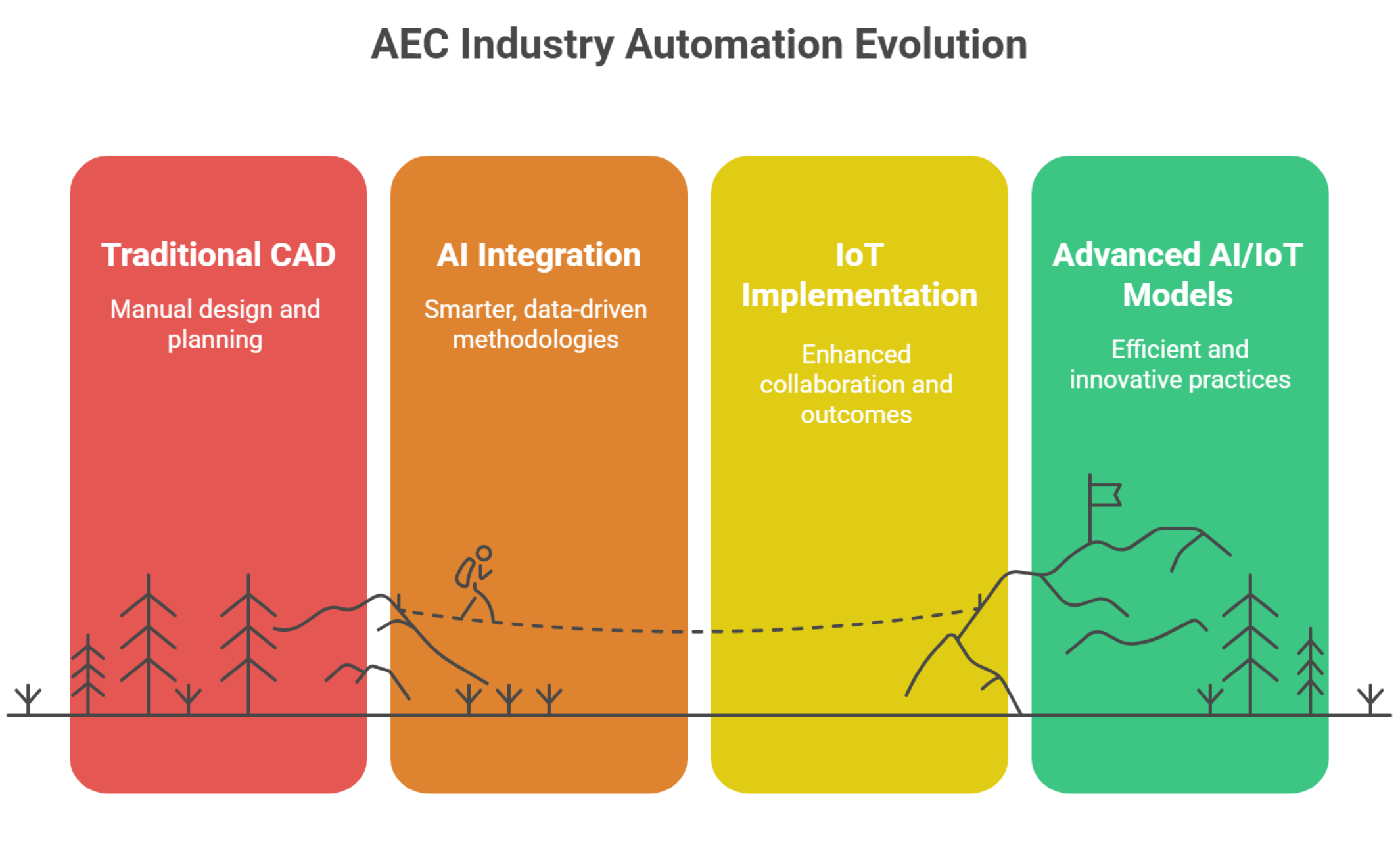

Automation in AEC is no longer a future concept. From BIM automation and parametric design to robotic scanning and digital twins, firms across architecture, engineering, and construction are integrating tools to cut manual tasks, reduce errors, and speed up delivery. This article breaks down how automation works in real projects, where it’s already improving outcomes, and how firms can start small, often with help from outsourced BIM modeling teams or automation-ready support like Remote AE.

Automation in the AEC sector isn’t just about construction robotics or fancy machinery on site. It includes digital workflows that minimize repetitive work across architecture, engineering, and construction. Think less about robots and more about scripts, plug-ins, and cloud tools that turn hours into minutes.

Real automation shows up in:

The impact? Fewer manual tasks, higher precision, faster iteration cycles. It’s not just about speed, it’s about consistency and scale.

The AEC industry faces real pressure. Deadlines are tighter. Skilled labor is harder to find. Digital coordination demands are growing. According to McKinsey & Company, rework and design errors are still responsible for massive cost overruns across global projects.

Here’s where automation in the AEC sector makes a difference:

Automation answers the pain. Scripts crunch data, AI flags clashes, and robotic scans spot site drift before it costs change-order money. Crucially, automation augments staff; it doesn’t replace the architect’s eye or the superintendent’s judgment.

Automation is real today across studios, engineering groups, and jobsites. Below are live use cases you can pilot now.

a. Architecture

b. Engineering

c. Construction

Across the AEC industry, automation isn’t just a time-saver; it’s a strategic advantage. When implemented correctly, AEC automation improves speed, accuracy, and coordination across all phases of a project.

Automation eliminates tedious, manual actions like title block updates, sheet renaming, or quantity takeoffs. Tools such as Dynamo, Revit API scripts, and BIM 360 extensions can condense hours of labor into just minutes.

With automation, design standards become consistent. Scripts apply element naming, dimensions, and annotation styles uniformly. This drastically cuts down errors in submittals and QA/QC checks, helping firms stay compliant with ISO 19650 or client-specific CAD standards.

Automated model syncing in shared Common Data Environments (CDEs) keeps distributed teams on the same page. Even if your teams are local, offshore, or nearshore, updates happen in real-time, no version confusion, no email back-and-forth.

Automation tools like 4D scheduling or 5D cost integration help projects move faster. Fewer RFIs, quicker redline responses, and automated quantity updates all lead to fewer delays in your critical path.

Remote workflows benefit the most. With automation built into platforms like BIM 360 and Autodesk Construction Cloud, firms using Remote AE’s virtual AEC teams can collaborate across time zones without slowing down. Leaders broadly expect AI and automation to increase efficiency; 78–79% of surveyed executives say AI will enhance their industry and creativity (Autodesk State of Design & Make 2024/2025).

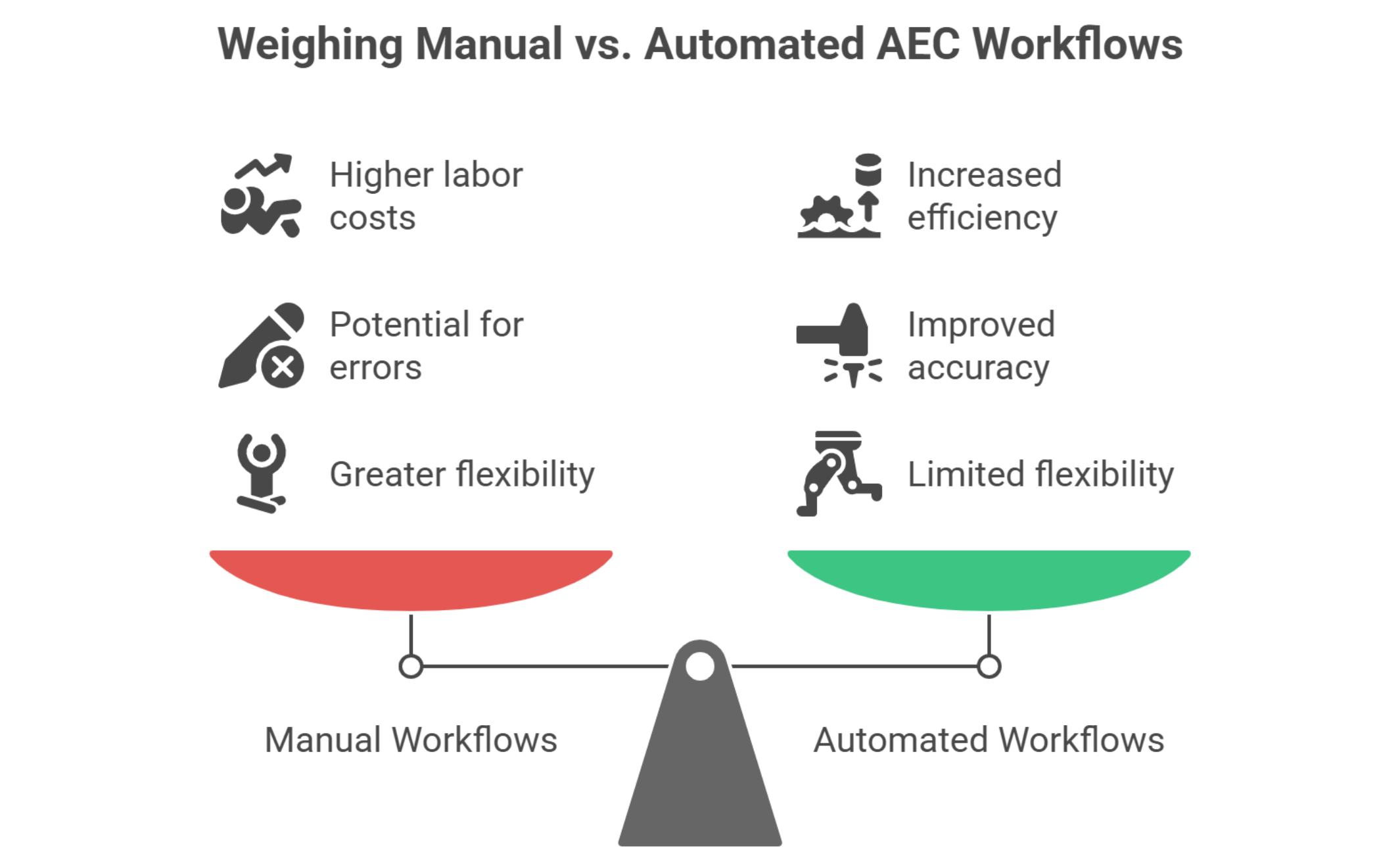

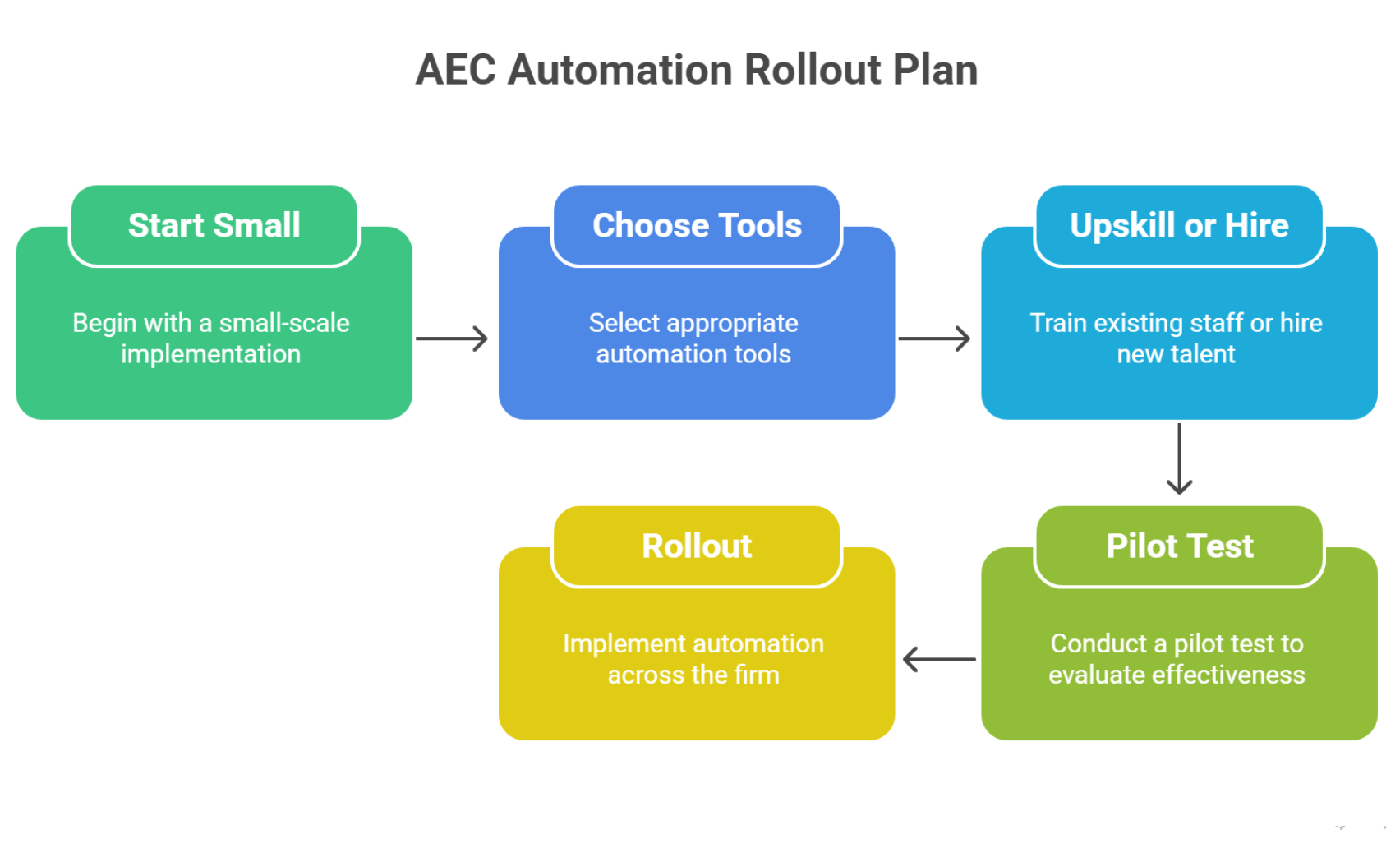

The power of automation in the AEC sector is unquestionable. However, below are a few key considerations to convert this power into actual outcomes for your firm:

You don’t need to build your automation strategy from the ground up. Outsourced AEC teams trained in BIM tools and automation scripts offer a fast, low-risk way to adopt modern workflows. These experts often bring reusable tools and proven workflows from similar firms. Tasks like Revit sheet creation, clash detection, and quantity takeoffs can be automated by remote teams already fluent in Navisworks, Dynamo, and Grasshopper. This saves internal resources and reduces training demands.

Proof from the field. When firms move work to a shared CDE and automate routine steps, cycle time drops. Gamuda reported an 88% time saving after standardizing in Autodesk Construction Cloud, evidence that well-run workflows plus the right tools move the needle (Autodesk Construction Cloud, Gamuda).

Remote AE’s virtual BIM teams include Revit drafters, MEP coordinators, and automation specialists. They’re both modelers and process-driven staff who apply automation in their day-to-day work. We establish SOPs, run test tasks, and report time deltas before scale-up. You keep control of standards and approvals; we provide steady hands to drive automation across real projects.

Tools like Autodesk Forma and TestFit are shifting early-stage design from manual modeling to AI-assisted decisions. These platforms generate layout options, evaluate site constraints, and analyze zoning within seconds. For architecture teams, this reduces upfront design time and helps land clients faster.

Once a building is operational, digital twins in construction models take over. With live inputs from IoT sensors, facilities teams can predict when HVAC systems will fail or identify unusual energy usage. Automation here means lower OPEX, fewer breakdowns, and smarter building operations.

As sensors, robotics, and LiDAR tools become cheaper and more accurate, project teams can automate field-to-office updates. For example, site scans using drones and LiDAR can feed directly into Revit, updating progress models with minimal human input. This creates a real-time digital thread from field to file.

AEC firms now prioritize hiring professionals who understand both design and automation workflows. Even if it’s someone fluent in the Revit API, Dynamo scripting, or BIM automation, these skills are in demand. Even outsourcing partners are expected to bring automation expertise, not just drafting ability.

Tasks like sheet generation, view placement, parameter updates, room tagging, and naming conventions are easily automated using Dynamo or custom scripts. These save time on repetitive actions.

Not yet. Robots assist with layout, scanning, and prefab assembly, but skilled trades are still essential. In 2025, expect robots to support, not replace, work on-site.

ISO 19650 defines how data should be structured and shared in a Common Data Environment (CDE). Automation scripts follow these rules to ensure file names, metadata, and deliverables meet project standards.

A BIM model is a design and documentation tool. A digital twin adds real-time sensor data, operations tracking, and maintenance insights to the model, making it useful beyond construction.

Start with Dynamo for fast automation in Revit. Add API developers if you need custom tools or integrations. Machine learning (ML) comes later, best for firms with lots of data to analyze.

Automation is changing how AEC teams design and deliver. If you’re ready to reduce errors, move faster, and scale without full-time hires, we can help. Remote AE connects you with vetted remote talent trained in Revit, Dynamo, BIM 360, and more. Fast onboarding. Flexible terms. Automation-ready from day one.

Talk to us today about building your automation-ready AEC team.

Other articles you may like: