Paula leads mechanical design at a busy MEP consultancy in Raleigh. The firm delivers HVAC and mechanical systems for laboratories, healthcare facilities, and office retrofits.

The project pipeline grew faster than internal capacity, putting key milestones at risk. She reached out to Remote AE. We placed a licensed mechanical engineering assistant as a full-time virtual assistant within four weeks.

The assistant was onboarded via our Remote AE team, and a mentoring and training session was implemented for the first 6 weeks. This allowed the virtual assistant to be plugged into Paula’s infrastructure & operations within the first 2 months of onboarding.

A dedicated project engineer who supports with production tasks, analysis tasks, and coordination. Paula’s senior team stayed on design & risk decisions. The assistant carried & supported the delivery forward.

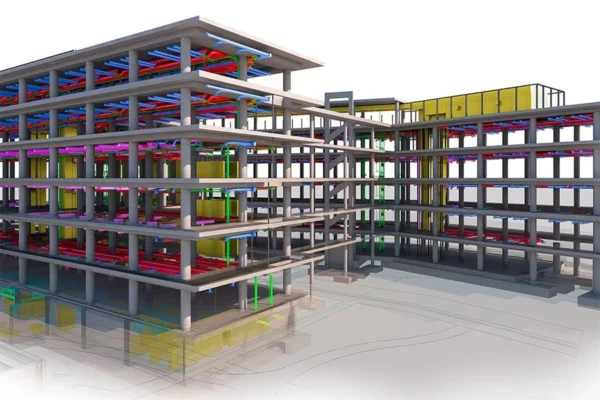

The assistant prepared, modified, and edited HVAC plans, duct and pipe layouts, and equipment schedules in AutoCAD/Revit. Submittal shop drawings were issued for review without stalls. Senior engineers gained back real hours for design checks and client calls.

Loads were calculated and airflow patterns reviewed using industry tools. Parking garages, plant rooms, and clean areas got focused attention for scope gaps. Fewer sizing revisions. Fewer loops between DD and IFC. Budgets held steady and deliverables were on time

The assistant built calculation sheets and quantity trackers. Research time decreased by about 23% through improved data preparation. Clear numbers supported quicker decisions. Materials and equipment were selected to minimize waste, resulting in a cost reduction of up to 9% compared to similar packages.

Calculation spreadsheets, method statements, and short technical memos were drafted on schedule. Engineers stopped wrestling with formatting and file hunts. Writing time decreased by approximately 33%, while documentation remained consistent across jobs.

Specs were checked against drawings and vendor data. Variances were caught early. Packages moved with fewer RFIs tied to the spec. Vendors and contractors were always aware of what was pending and what had been approved.

Daily follow-ups, schedule updates, and issue lists kept the team aligned. Risks were flagged early. Paula’s critical paths stayed intact. Meetings focused on decisions, not status.

Energy models were run to test VAV strategies, heat recovery, and control logic. Recommendations were practical and buildable. Owners saw lower predicted consumption without sacrificing comfort.

Time to staff: four weeks.

Capacity gained: senior leads reclaimed meaningful weekly hours, mitigated real risk, and provided a higher quality of service to clients & projects

Delivery: fewer redesign cycles and smoother submittals.

Cost signal: measurable savings from better project management & efficiencies, change order processing, scope gap reviews, and proper material quantification and estimates

Remote AE’s Virtual Engineering Assistant service gives mechanical teams dependable capacity without adding local headcount and 65% expense savings on staffing costs. Need similar support for your projects? We’re ready to help.